Accelerated Weathering

Accelerated Weathering

QUV light is causing chemical degradation of coatings and becomes visible in various forms such as loss of gloss, fading of colour, chalking, blistering etc. Natural outdoor exposure is often used but time consuming and therefore accelerated weathering testing methods are widely used in the coatings industry.

Such accelerated methods are often conducted in equipement such as QUV and usually operates with cycles of radiation and condensation. ISO 16474 is a typical method used but many more exist.

Accelerated weathering testing can be used as test on itself where it is very suitable to compare the influence of formulation variations on gloss- and colour retention. In combination with for instance salt spray, the QUV cycles are used to introduce degradation and temperature stress on the coating.

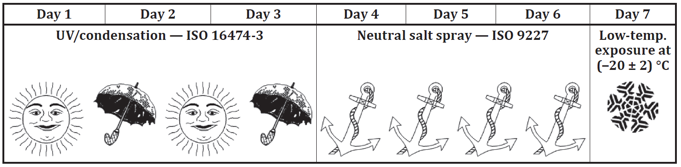

A good example of the latter is the cyclic ageing test of ISO 12944 - 9 using the following sequence of testing conditions:

Step 1 – 72 hours UV/ condensation according to ISO 16474-3, method A (4 hours UVA-340 and 4 hours condensation at 50 °C)

Step 2 – 74 hours of neutral salt spray according to ISO 9227

Step 3 – 24 hours exposure at – 20 °C.

A full cycle therefore take 168 hours ( 1 week). Total test duration depends in the required specification.

Such accelerated methods are often conducted in equipement such as QUV and usually operates with cycles of radiation and condensation. ISO 16474 is a typical method used but many more exist.

Accelerated weathering testing can be used as test on itself where it is very suitable to compare the influence of formulation variations on gloss- and colour retention. In combination with for instance salt spray, the QUV cycles are used to introduce degradation and temperature stress on the coating.

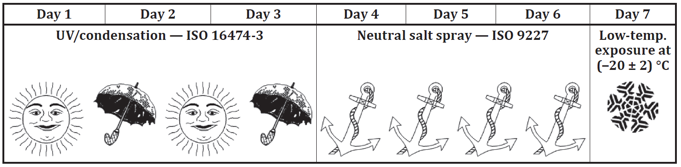

A good example of the latter is the cyclic ageing test of ISO 12944 - 9 using the following sequence of testing conditions:

Step 1 – 72 hours UV/ condensation according to ISO 16474-3, method A (4 hours UVA-340 and 4 hours condensation at 50 °C)

Step 2 – 74 hours of neutral salt spray according to ISO 9227

Step 3 – 24 hours exposure at – 20 °C.

A full cycle therefore take 168 hours ( 1 week). Total test duration depends in the required specification.