Electrochemical testing

Electrochemical testing

For the usual corrosion testing methods, the performance of coated panels is determined by rust creeping from an artificially made scribe. However, by introducing a coating defect the test is more about the damage-protective properties of the coating in relation to the substrate than the corrosive protective properties of the coating system itself.

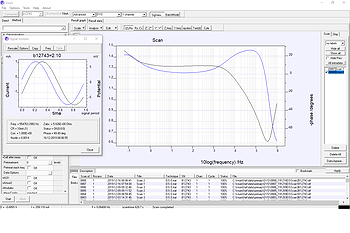

The use of electrochemical evaluation techniques such as Electrochemical Impedance Spectroscopy (EIS - ISO 16773 ) overcomes avoids making damages to the coating and actually determines the intrinsic protective properties of the coating itself. In fact, as EIS is non-destructive it is very suitable for evaluation of the anticorrosive properties of coatings in the field. EIS can provide more insight about the electrochemical processes within the coating and at the coating/ substrate interface. Furthermore, EIS provides quantitative data and is fast too, standard test duration is 3 weeks but usually tendencies are visible within 1 week.

Most important is to realize that literature shows EIS has greater correlation with real world performance than cyclic corrosive testing does. The thesis by W.M. Bos, Prediction of coating durability: Early detection using electrochemical methods, provides excellent reading material about EIS and coating testing.

For coating developers, EIS is ideal for production quality control, raw material evaluation and product comparison.

For coating users or specifiers, EIS is ideal to be used in specification requirements, vendor rating, performance analysis and maintenance planning.

More recently an alternative process known as ACET (Accelerated Cyclic Electrochemical Technique - ISO 17463) has been developed, which produces very rapid breakdown of coatings under cathodic polarisation. See for instance the work of Mr José Javier Gracenea for more information. Within our research programs we have conducted some test series but have not (yet) found suitable settings resulting in reliable data. However, we would be very much capable to carry measurements according to your desired settings.

Likewise, we have experience in conducting OCP (open circuit potential) measurements on coating systems.