Corrosion testing

Corrosion testing

Several international and/or national bodies have issued norms for testing. Below a list of the most common standards used;

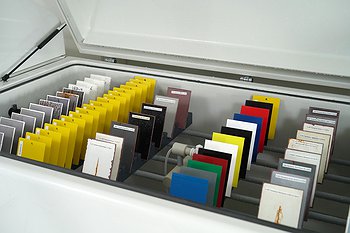

- Salt spray testing ISO 9227, ASTM B117

- Humidity testing ISO 6270, ASTM D2247

- Immersion in liquids ISO 2812, ASTM D870

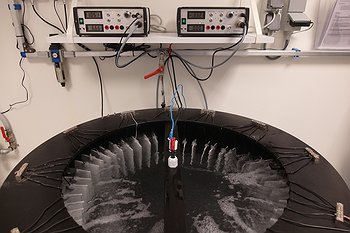

- Cathodic disbonding ISO 15711

- Accelerated QUV radiation ISO 11507

The most well-known standard that relates coating system and corrosion testing is ISO 12944, which consists of nine parts. ISO 12944 – parts 5, 6 and 9 are especially relevant here and proposes systems for various corrosive conditions as well as indicates the level of testing to be carried out.

It is also possible to combine conditions and perform so-called cyclic corrosion testing. It is believed that such combination of testing conditions give a better correlation with real world results than using a single test condition on itself. There are many standards developed by international bodies but also by companies such as the automotive industry.

ISO 20340 or Norsok M-501 are often referred to when using cyclic corrosion testing. However, ISO 20340 has been superseded by ISO 12944 – Part 9, which links protective paint systems and laboratory performance test methods in a similar way as ISO 12944 Parts 5 and 6 do, but more specific to severe corrosive environments such as offshore and related structures. While the types of test methods used by parts 6 and 9 are similar, there are differences in the test durations as well as test procedures. See breakdown of ISO 19444 testing requirements.

CCT-Pro is able to carry out the full spectrum of tests required by ISO 12944 parts 6 and 9, which means cyclic corrosion testing, immersion testing and cathodic disbonding.